NEW PACKAGING SOLUTION SAVES TIME FOR BOTH EMPLOYEES AND ROBOTS

Heating elements from one of Sweden’s large industrial companies are being packed by robots and are now shipped in a Heavy Duty corrugated cardboard solution from FARUSA Emballage, who won the assignment thanks to a number of time- and robot friendly factors.

- It is crucial that the boxes are easy and quick to prepare, and that they have a uniform height, so that our robots can pack the heating elements without problems, says Stefan Kraft at Backer BHV AB. At the Swedish company Backer BHV AB located Sösdala in Southern part of Sweden, heating elements are made of aluminum for heating e.g. train carriages and residences.

The Swedish company is the headquarters of the Backer-group. The Backer group is market leader in the Nordic countries and one of the leading suppliers in Europe of products, components and systems for electric heating and heating regulation

The Swedish company is the headquarters of the Backer-group. The Backer group is market leader in the Nordic countries and one of the leading suppliers in Europe of products, components and systems for electric heating and heating regulation

The Backer Group is part of “Nibe Element” at the world-wide Swedish industry group Nibe AB. Backers aluminum elements are designed to enhance older traditional heating systems using either convection or thermal radiation. They are manufactured in a department which counts 10-15 employees in a robotic production. Here the elements are packed in large Heavy Duty corrugated cardboard boxes which bring them safely out into the world to dealers, large contractors, train manufacturers etc.

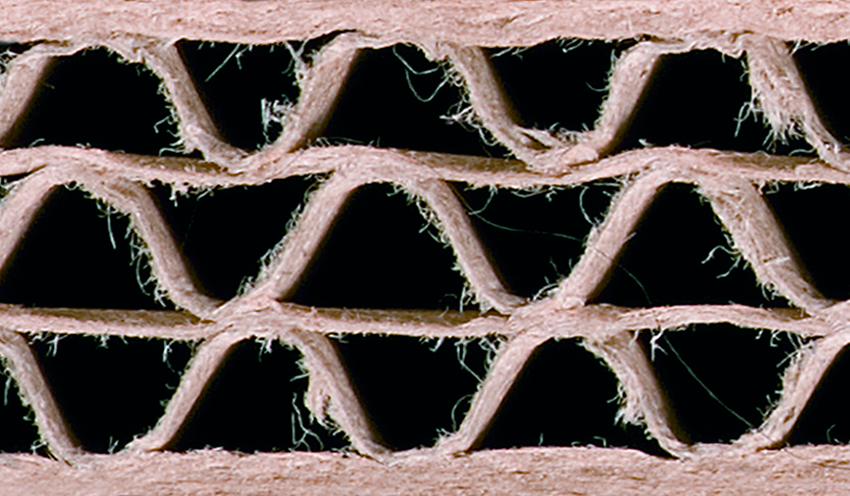

HEAVY DUTY PROVIDES HIGH PROTECTION

- Depending on the size the heating elements are packed in a box which is either 1200 or 1600 mm long, 800 mm wide and 470 mm high. The elements are placed lying next to each other in layers, between which cardboard is placed. When the box is full, it holds 100-150 elements and weighs about 80-250 kg explains Stefan Kraft, Strategic Purchaser / Nibe Element, Backer BHV AB.

- This is actually a relatively modest weight for at Heavy Duty corrugated cardboard box, which has roughly the same strength as transport packaging of wood-based materials and can therefore also carry and protect much heavier products, says FARUSA’s district manager in Sweden, Eddie Johansen, who points out that the stacking strength is correspondingly high.

- One of the other key advantages is that the Heavy Duty material weighs much less – for example less than half of what ordinary plywood weighs. This is significant when the packaging is to be handled both in connection with packing and with unpacking / disposal. Thus, a single operator cand handle it himself, he says.

- Simple construction and great uniformity save time.

Stefan Kraft agrees that it is practical for the packaging to be manageable for a single operator.

- But the construction is also extremely important, he emphasizes.

- While it is our robots that pack the elements, it is our operators who raise and prepare the boxes. Here it is very important how simple and not least how fast it can be done - and he speaks from experience. The solution from FARUSA Emballage has replaced an earlier solution in corrugated cardboard from another supplier.

- It was a construction that took five minutes to raise and assemble because it was far more intricate and complex than our new solution from FARUSA. This new solution takes only half a minute to get ready including gluing cardboard joists in place, which prepares the box to be moved with a forklift / truck.

- At the same time, it is crucial that the boxes are completely uniform when raised. The previous solution had integrated pallets which caused quite large fluctuations in height and resulted in problems for the robots. But we are fortunately spared for this problem with our new solution, says Stefan Kraft, who also emphasizes the practicality of the fact that it only takes a few hours to get new supplies from FARUSA if needed.

The boxes used are tailormade and stocked at FARUSA Emballage, which is the only manufacturer with 100% focus on Heavy Duty in Scandiavia.

Do you wish more information about Heavy Duty packaging solutions or further information?

Please contact us at:

Phone: +45 4434 0999

emballage@farusa.com

#HeavyDutyLøsninger #transportemballage #deneneste