Dangerous Goods with heavy duty protection

Whether you talk to FARUSA Emballage A/S or “Center for Packaging and Transport” at Danish Technological Institute you need to pay close attention when they talk about packaging dangerous goods.

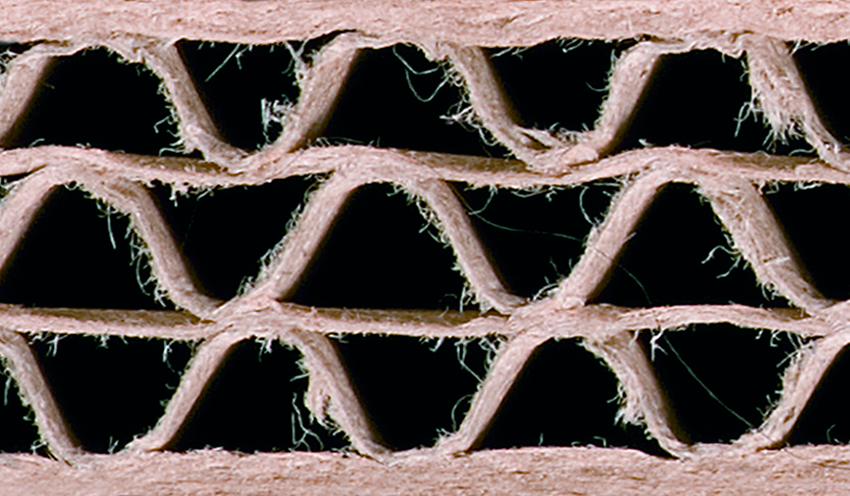

Both parties have extensive knowledge about the comprehensive and complex set of rules that regulate the area; respectively as a supplier of Heavy-Duty corrugated packaging boxes and as the authority that tests and approves these for the purpose.

Transport of dangerous goods such as explosive, flammable, toxic or corrosive substances have been regulated worldwide for more than 60 years based on UN recommendations. It is an expert group under the UN that classifies all dangerous goods with a UN number – one of three different groups of hazards, which also determines the requirements of the product’s transport packaging.

Many the packaging we manufacture are used for the transport of dangerous goods. Genuine Heavy Duty corrugated cardboard, as ours is, can pretty much accommodate the full range of the UN recommendations, which apply to packages with a net weight of up to 400 kg. We thus have a packaging in size 1200 x 1000 x 980 mm, which is drop-test-approved for 320 kg or 400 kg – depending on the danger of the contents, says manufacturer Arne Hammer from FARUSA Emballage A/S. FARUSA is the only manufacturer with 100% focus on producing Heavy Duty corrugated packaging in Scandinavia.

Type approval according to transport conventions.

The ingredients in the recipe which transforms a Heavy Duty corrugated packaging into an approved dangerous goods packaging is as follows:

- A type-approval pursuant to one or more of four regulations for different modes of transport – respectively by road (ADR), by rail (RID), by sea (IMDG) and by air (IATA/ICAO).

- An UN-number that identifies the content of the specific dangerous goods in one of three package groups.

- As well as a final so-called selective test, i.e. a test of the specific transport packaging with the current content.

“Center for packaging and Transport” at Danish Technological Institute type-approves packaging according to the number of kilos. The test for a Heavy Duty corrugated cardboard packaging consists of three different tests:

- The Cobb Test, which measures how much water the material absorbs

- A Stacking test, which is always performed with a pressure corresponding to a three-meter stacking column

- And a drop test – on five different edges and corners from respectively 1.8, 1.2, or 0.8 meters – according to the requirements of the three package groups, “X” (most dangerous), “Y”, and “Z” (least dangerous) respectively.

Manufacturer Arne Hammer with a couple of FARUSA’s Heavy Duty corrugated packaging for dangerous goods. The box on the right is a “4GV”-type, which can be used without further testing. However, it can only hold half of what it could have if it had been tested for its specific content. On the other hand, it ensures great flexibility and fast delivery.

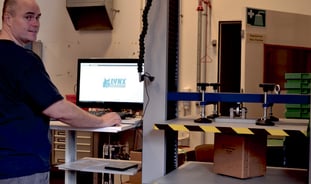

Manufacturer Arne Hammer with a couple of FARUSA’s Heavy Duty corrugated packaging for dangerous goods. The box on the right is a “4GV”-type, which can be used without further testing. However, it can only hold half of what it could have if it had been tested for its specific content. On the other hand, it ensures great flexibility and fast delivery.Morten Pedersen (at the right) is preparing a drop test of one of FARUSA’s Heavy Duty corrugated cardboard boxes fra 1.8 meter, which is required in packaging group “X” (most dangerous).

Selective testing with the specific product

When FARUSA emballage, with whom we have had an ongoing collaboration for many years, requires an approval of a dangerous goods packaging for a specific customer / a specific product, they supplement the type-approval with information about the weight and nature of the product identified by the UN Number. Then we perform a drop test according to the product’s hazard code and thus the relevant package group, explain Product Manager Morten Pedersen and Senior Consultant Søren Henriksen, Center for Packaging and Transport the Danish Technological Institute. An approved Heavy Duty corrugated packaging will then have to bear a label with the following numbers and letters: “4”, which means that is is a box; “G”, which indicates that it made from cardboard material; “X”, “Y”, og “Z” – depending on the package group in which it is approved; as well as a figure for the number of kilos for which the packaging is approved. The label can be, for example: 4G x 100 / Y150 / Z200.

Speed is an important parameter.

At FARUSA Emballage, in accordance with the Transport Conventions, a special packaging is also offered, namely a V-classified combination packaging. That means a “4GV” packaging, which can be used with all types of inner packaging, and of which FARUSA is the only Danish manufacturer.

It is relatively extensive to have a selective test performed every time we are going to deliver packaging for a new dangerous good product. Thus, we have invested in a 4GV type approval performed in package-group “X” with the most fragile inner packaging. The 4GV box is packed with 30 mm package filling around each inner packaging, as well as in the top and bottom, and must be secured by using heavily reinforced tape. After an approval test, in accordance with the regulations, half of the product weight is removed. This way we have a dangerous goods packaging, which we can deliver without further approval to customers who may need smaller series or fast delivery, Arne Hammer explains.

The stacking test at Danish Technolocial Institute is always performed with a pressure corresponding to a three-meter stacking column.

One-Stop ensures speed.

The Danish Technological Institute, which is an accredited testing institute, is very much aware of the fact that speed can be an important parameter: - Our testing laboratories are just one of several business areas. We also offer guidance and implementation of pilot- and developments-projects, and since 1989 we have also had the authority role in “Packaging and Transport” when it comes to approving packaging for dangerous goods, Morten Pedersen and Søren Henriksen point out.

Thus, we are seriously a One-Stop shop, which e.g., is an advantage for those manufacturers who constantly trying to optimize packaging. If a test does not go well, it is much easier to go through the approval procedure again at our facilities than if you must go back to several instances. And for most companies, speed is important, so we also aim to have a good lead time, they say.

Product Manager Morten Pedersen and Senior Consultant Søren Henriksen at the bookshelf with the various regulations, including i.a. The ADR Convention. The ADR Convention is renewed every two years.

Product Manager Morten Pedersen and Senior Consultant Søren Henriksen at the bookshelf with the various regulations, including i.a. The ADR Convention. The ADR Convention is renewed every two years.